Stay in touch with the latest on COVID 19 in South Africa

click here for more information

CSI MINING

nothing else, but quality

Cnr Botha & Pretoria Rd, Petit, Benoni 1501

Have a question call us now: +27 100030127

products

cells

The introduction of the patented UNICELL®

The introduction of the patented UNICELL® in the mid-1980’s is universally recognized as one of the great contemporary innovations in tankhouse technology. There are now more than 40,000 UNICELL® in operation around the world. Various sizes are manufactured to suit customers’ specific tankhouse needs.

Advanced Technical Composite:

Our patented, advanced technical vinylester-based composite is specifically designed to provide superior chemical resistance and mechanical durability, withstanding the extreme environment of a tankhouse where other materials fail.

Non-conductive FRP Rebar reinforcement

Fiberglass Reinforced Plastic Rebar provides structural protection against catastrophic failure to each UNICELL® without the possibility of creating short circuits.

Monolithic Construction:

The UNICELL® is the only monolithically cast electrolytic cell with integral overflow/ decant and inlet piping systems. Eliminating cold joints and seams from cell designs has reduced long-term maintenance costs.

Gel Coating and Mat:

This process provides a smooth surface, additional layer of corrosion protection, improved electrolytic flow and higher slimes recovery.

insulator blocks

CSI has developed a world class innovative Insulator block called the CSI PMC Insulator Block. These blocks are

commonly known as Spacer Blocks or Capping Blocks. The CSI PMC insulator Block is an acid resistant spacing

block that comes in a number of designs, tailored to our customers specific needs. The blocks are designed for the

seating & spacing of Electrodes (Cathode & Anodes) in an acid bath, allowing for better, copper, nickel, zinc, cobalt

and manganese electro-winning efficiencies

feature and benefits

Accurate spacing of electrodes in cells, reduced risk of electrodes shorting out against each other.

Efficient placement and removal of electrodes in and out of the cells during harvesting cycles.

Decreased power loss over the electro-winning circuit.

Easy plug and play design.

Shorter units allowing for easy replacement, and less product waste.

High resistance to the acidic environments they are subject to. The blocks contribute immensely to the outputs of the electro-winning process making for a more profitable business.

EDGE STRIPS

We supply U shape, H Type, Cross slotted and Omega Edge strips. All these strips are manufactured to specifications and needs of customers.

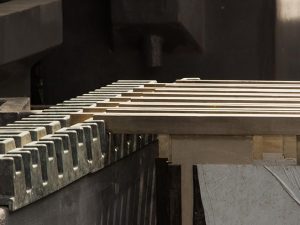

busbars

We provide turn key solutions that ensure quality, performance and maximum efficiency in the harvesting of base metals. Whatever shape the bus bar system is, whether dog bone, U-shape, square or triangular, we can provide a solution.

DEMISTER BALLS

Our demister balls reduce acid mist generated by electrowinning metals from Acidic Electrolytes, which is dangerous to human health and damages building structures. Most of these acid mist particles impact or condense on the balls, then return harmlessly into the solution. Demister balls allow unobstructed retrieval of the cathode and fail to become trapped in the copper deposits.

CATHODES

Titanium and Stainless steel cathodes made to client specifications. These durable cathodes are manufactured in South Africa and used across Africa and the rest of the world. They are designed specifically for mining applications. This header bar out performs any other header bar on the market in the short and long term. Robotic Weld benefit ensures seamless joints as like materials are joined – Stainless Steel Blade to Stainless Steel Header Bar, this greatly contributes to many years of trouble free usage in the Electro-winning and Electro Refining Environment. Unlike most header bars where the stainless tube is cladded around the copper, our header bar uses technology that “extrudes” the copper through the square steel tubing. This method eliminates the ingress of acid between the copper and stainless steel tube, which ensures that plating of copper onto the cathode is much more efficient.

CATHODE REFURBISHMENT

We provide refurbishment of existing cathodes on site or off site. Having a cathode maintenance program can be a massive cost saving for the mine. We have 10 years’ experience in this field with skilled staff to manage this program. More added advantages are local empowerment, cathode turnaround time and availability of cathodes.

ANODES

Customers can choose between lead or titanium anodes. Titanium header bars are much more expensive, however increase efficiencies in the Electrowinning process and decreases health hazard. Our lead anodes are rolled and decreases the possible contamination in the electrolyte solutions. We provide lead anodes to maximize the extraction of the base metals in the electro-winning process. The header bars are specialized and the welding is super fused onto the lead anode blade.

ANODE BUTTONS

Anode Insulator Buttons / Spacer Buttons. male and female thread, screwed together, fit into a standard 22mm hole. Used for Insulating / Spacing purposes between Anode and Cathodes. Shemesh Anode Spacers are highly durable specialized components.