Stay in touch with the latest on COVID 19 in South Africa

click here for more information

CSI MINING

nothing else, but quality

Cnr Botha & Pretoria Rd, Petit, Benoni 1501

Have a question call us now: +27 100030127

customers & projects

212 x Electrowinning Unicells, 208 in production & 4 Spare (Tailored design)

212 x Electrowinning Unicells, 208 in production & 4 Spare (Tailored design) 212 x overflow coversand flow control devices...

212 x overflow coversand flow control devices...

212 x Electrowinning Unicells, 208 in production & 4 Spare (Tailored design)

212 x overflow covers and flow control devices

212 x crane locating devices

208 x Electrowinning Unicells installed

CSI started the production of this project in the first quarter of 2010. This was a high profile project where many stakeholders kept a close eye on its progress, labelling it as high priority, with penalties associated within it delivery timelines.

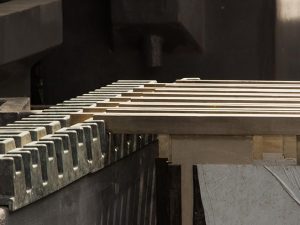

CSI began (after design confirmation and fit for purpose analysis) by manufacturing three unicell moulds, one being a Left end, another being a right and the third being an intermediate mould. These moulds took approx. 12 – 16 weeks to manufacture, with an average weight of approx. 8 tons per mould. These moulds were beautifully manufactured to within a tolerance of 10mm along a length of 8m and 6mm on the width of 1.3 – 1.5m.

Production of the polymer concrete unicells took place shortly after the mould signoff. With the challenges associated with the production start-up along with the inclusion of experienced CTI polymer casting expert Dirk Mortier, CSI worked hard to get a handle on its production. Document after document from QC’s and project management ensued as the days & months progressed, and thus the compilation of data books almost drove itself.

The months ahead were tedious, but despite these challenges CSI finally came to production completion, without any delay penalties……at this point focus changed from Production to Installation.

Installation with its own challenges was completed where 104 pairs of cells were installed in the RMBR Rustenburg nickel tankhouse and still in full production today.

✔️17 860 x PMC Insulator Blocks(inter-connected;

tailored design)...

5000 x Stainless Steel Cathodes(Tailored Design)

17 860 x PMC Insulator Blocks(inter-connected; tailored design)

The first quarter of 2012, accelerated us into the manufacture and supply of both insulator blocks and Stainless Steel 316L Cathodes. The insulator blocks were an intriguing design put together by some of the most innovative engineers South Africa have ever seen, running into a streamline supply over its manufacture and supply lifetime.

.

✔️160 x weir plates. 160 x overflow cover...

160 x Electrowinning Unicells

160 x distribution feed manifolds c/w S/S holding brackets

160 x weir plates

160 x overflow cover

A project, that also kept CSI excitingly busy from the first quarter of 2012. Production was started, and proceeding into winter manufacturing was slowed due to extremer Weather conditions not conducive to the unicell production process. Other than that, along with the Passion of our Production Manager, a project that was completed well and within budget.

✔️94 x Feed Distribution Manifolds

✔️94 x Demister ball retainers...

94 x Electrowinning Unicells(Tailored design)

94 x Feed Distribution Manifolds

94 x Demister ball retainers

Moving swiftly into 2013, CSI became the supplier for Unicells and associated products to the Kipoi Project. An impressive unicell design showing strength and integrity, showing product manufacture with a difference

✔️64 x distribution feed manifolds c/w S/S holding brackets

✔️64 x Weir plates

64 x Electrowinning Unicells(Tailored design)

64 x distribution feed manifolds c/w S/S holding brackets

64 x Weir plates

64 x Underflow Baffle plates

726 x PMC Insulator Blocks(inter-connected; tailored design)

64 x Electrowinning Unicells; 726 x Insulator Blocks fully installed on site

The first quarter of 2014 brought us into production of 64 Unicells and over 700 Insulator blocks for the Tshudi Copper Project, up in the North of Namibia. To say the least, a great project to have worked on with a great outcome for both the production and installation of the supplied products.

✔️78 x distribution feed manifolds c/w S/S holding brackets

✔️78 x weir plates

78 x Electrowinning Intermediate Unicells

78 x distribution feed manifolds c/w S/S holding brackets

78 x weir plates

78 x Underflow Baffle plates

800 x PMC Insulator Blocks(inter-connected; tailored design)

1248 x PMC levelling Shims

1 x Unicell lifting spreader beam and Slings (for installation)

Solely a Product supply project that commenced in June of 2015, with a consistent ramp up, to steady product manufacture, with production completion in November of the same year and Unicell loading and despatch running for 3 months from mid to end September 2015.

✔️48 x distribution feed manifolds c/w S/S holding brackets

✔️48 x S/S 316L weir plates...

48 x Electrowinning Unicells

48 x distribution feed manifolds c/w S/S holding brackets

48 x S/S 316L weir plates

48 x Underflow Baffle plates

2 x Tank house Floor Sumps

1273m² of Tailored acid resistant floor lining

After years of updating quotations and running different quotation senarios, we managed to get the rehabilitation work for tankhouse 1 & 2 late in August 2017.

✔️1000 cathodes

✔️We commissioned one of the tankhouses with our products